Vintage Sofa Redo

My most recent and one of my favorite makeovers (I should look back, do I say this about every project? But every project does have a bit of my heart, but I really, really love this one), was of this vintage sofa. I spotted this sofa at an estate sale in my neighborhood. I wouldn’t say that it was love at first sight, but I saw its potential, and thought it would be a reasonably strait forward makeover. I liked the idea that there wasn’t a lot of reupholstering that needed to be done to the structure other than the base, although there would be a lot of sewing to replace the fabric on the cushions. Anyway, it was good option, I just thought I would let fate decide. This estate sale allowed for bids to be placed, so I placed an offer for a 50% price if it didn’t sell by the end of the first day of the sale. I got it, obviously :).

At first I thought I would redo the sofa with German grain sacks with writing, but somewhere along the way, I fell in love with the idea of using grain sack fabric with caramel colored stripes. This is not a color that I have worked with often or at all except for making a couple pillows for a client. And now I am hooked. I bought two 4 1/2 yard rolls of this grain sack fabric for one of my go to shops, Grain Sack. This lovely shop gave me a coupon code for 10 percent off for my readers, it is good through 7/1/2022. The code is: PENNYANDIVY10. I have bought from this shop since 2016, they have hundreds of high quality options of vintage handwoven hemp linen fabrics. I have loved every order and they always arrive clean and nicely packaged.

This fabric made me so excited about the project. I loved the tone of the caramel color, and the nubby weave of the fabric. Even with the 9 yards of it, there was not enough for the sofa, so I had to find enough of similar toned hemp linen to piece together to get this project started. Piecing together fabric is usually the only option when using vintage fabrics due to the finite supply. Fortunately I love the look, it feels cozy and homey to me.

Before I got into the sewing part, I knew I wanted to redo the dated look of the wood. It did cross my mind that maybe I could strip the wood, there are lots of beautiful projects lately of stripped wood circulating around the internet. But I recently tried stripping the finish off a pair of dressers and let me tell you it is not for the faint of heart, it is really messy and takes A LOT of time. I did develop a system and am not totally scared off of trying to strip furniture again, however I wanted a break. I was also worried about damaging the caning on the sofa during the stripping process, so painting it was THE decision.

I chose one of my favorite paints, Miss Mustard Seed Milk Paint, Schloss. It is the perfect warm griege that compliments the oatmeal color of the linen. Before painting I cleaned the wood, and lightly sanded it. The finish on the sofa was very shiny, milk paint has trouble adhering to a nonporous surface, so I added its milk grip bonding agent. It worked like a charm, there was still some chipping, but just the right amount. If you want a lot of chipping, you can apply the milk paint without the bonding agent to a nonporous finish, and that is likely what you will get, although there are no promises. This paint has a bit of a mind of its own, but I am almost always happy with the end product and love what it does. I did two coats of milk paint and lightly sanded it. To seal the paint I used the General Finishes Flat Out Topcoat. This is an easy to use water based top coat that doesn’t add any sheen. I did 3 coats of the this just make sure the durability was strong and present, and that is what the instructions on the can advised :).

My next part to attack was getting the cushions in working order. These were something. This sofa was incredibly sturdy and made with super high quality everything, except the seat cushions. The seat cushions were a thin down envelope with springs in them. It was a terrible choice of ingredients to make a cushion in my opinion. There was a thin foam layer that was used to either hold the springs in place or add cushion. Either way, the foam was disintegrating and the springs were a mess. And there was burlap mixed in too.

I removed that train wreck and was left with a thin envelope of down. This was in great condition, and all the feathers were IN the fabric, which is huge. Chasing feathers is not my favorite.

I used this technique that I described in this post to replace the springs with 3 inch foam and still using the down envelope. I finished up by wrapping the cushion in two-three layers of dacron to make a full cushion. I was very pleased with these cushions and the quality of the felt very comfortable. Thankfully the back smaller cushions for the back were in great condition and were all down filled. No springs. I did wrap these with dacron to make them full also.

Now the cushions needed new covers. I made them using this technique in this post. Although I did not need to make a pattern for the cushions, I just measure the fabric from the original cushion and since they were rectangles I followed those measurements. I did not measure the original cushions because they were not full and not in good condition. But the fabric was and gave me accurate measurements. I made six cushion covers. It took awhile. But it was worth it.

All that was left was reupholstering the seat base. At this point I realized I unscrew the base and remove it to reupholster it. I wished I had realized this when I had painted it. I need to do a little painting to cover the missed spots.

Anyway, having it removed I was able to wrap the base almost like a present. But first in ordered to get a piece of fabric that size, I used some natural duck canvas pieced together with the hemp linen. The canvas is not seen because the cushions will cover it, and if someone does get a peek of it then its somewhat similar color to the hemp linen, and it is durable fabric. I whipped stitched the under side of the seams of the new fabric to the old fabric (the old fabric was in good condition, so no need to remove since I would be covering it entirely). You can see how I did this during this makeover post. Then I wrapped the fabric around the corners like you would wrap a present and stapled the fabric in place in the underside.

I replaced this bottom and screwed it into place. I did notice about an 1/8 inch gap under this bottom and the wood. I corrected it by adding a 1/4 inch piece of cording wrapped in hemp linen and sewn in place using a zipper foot. Taking this cording I glued in place with a hot glue gun with the seam in the back.

I love how this sofa turned out. I love how comfortable and sturdy it is.

I love that it is 94 inches looong. I love that it is unique but somewhat versatile in its style. I went through my stash of fabrics and tried out a variety of different styles of pillows and I think that they all work.

This sofa is currently for sale the charming shop, Anthology Home, in Waukesha. It is such a sweet reward to see the end result in this beautiful space after a couple of weeks of working on it.

The Makeover of Two Settees Part Four: The Decking

We have arrived at the final part of this series of DIY reupholstering these two settees, which is replacing the decking or the bottom part of the settee fabric. I recommend reading all the directions before beginning.

REPLACING DECKING/BOTTOM FABRIC

1.I began this project by cutting out a piece of natural colored duck canvas that covered all but approximately 3 inches on the outside of the seat, as pictured:

I found no need to remove the previous fabric on the bottom because it was in good condition and I could cover it up.

By using the duck canvas, I was able to use less of the vintage hemp linen. If you notice most upholstered pieced with removable cushions have plain fabric on the bottom pieced together with the fabric that is showing on the outside (and likely the more costly fabric).

2. I then added at least 8 inches of the hemp linen fabric to all the sides, it needed to be enough fabric to cover a couple inches on the seat and to pull through onto to the sides and nail in place with a fold.

I did a lot of estimating and piecing fabric together for this process. Because of the look I was going for, I was able to piece fabrics together, which made the process much less exact.

3. I sewed the strips of hemp to the canvas with a double seam and created this fabric piece to cover the entire bottom of the seat:

4. Next up is tucking the fabric around the legs and arms of the settee. This is the trickiest part in my opinion. Proceed carefully. I love using these scissors for the process of slowly cutting into the fabric so that the fabric lies flat, but not too much that any cuts in the fabric are visible. I always try to over estimate on the fabric needed and then make more cuts where in order to get the placement right.

5. Once I am pleased with the way the fabric is placed and tucked under, I flip up the front strip, and do a quick whip stitch at the seam on the bottom to the fabric on the seat. I use a curved needle and upholstery thread to do this.

6. Now that is secure, it is time to tack the outside bottom to the frame. I like using carpet tacks for this and I also like my lightweight upholstery hammer to minimize damage to the wood frame. I fold the fabric under so no raw edges are exposed and hammer into place.

This is another case where I did not mind everything not being quite exact due to the slightly rustic look I was going for. There were times I need to add a fold to the fabric to get it to lie flat and I was just fine with that.

AND WE ARE DONE

Remember where we started from?

Thank you for checking out this post. Feel free to contact me with any questions at pennyandivydecor@gmail.com.

Makeover of Two Settees Part Three: Cushion Cover

To make a cushion cover(s), I started with my pattern that I created for the seat of the settee. I mentioned this process in the last post, but it would be helpful to have it here too:

CREATING A PATTERN FOR A CUSHION

- I took a large piece of paper similar to wrapping paper and placed it on the seat of the settee:

2. I traced around the seat to and cut out the paper:

I cut the paper a bit too short in the corner here so, I corrected with with a bit more paper and tape.

CUTTING OUT FABRIC PIECES FOR THE CUSHION

- I first cut out a top and bottom of cushion using a the pattern I created and ADDING 1/2 INCH around the pattern for seam allowance.

Since I was using a grain sack in which one side was not wide enough to cover the top, I made cuts on the bottom side, so I could create a piece large enough for the top of the cushion. If you are here, you are likely to know that vintage hemp linen is my thing. The quality and history of the fabric is very special to work with. Here is a list of some of my favorite shops to buy this kind of fabric: Brocante und Antikes, Objekts1, Grain Sack, Linens by Sabine, Antique Monkeys, The Textile Trunk

Since I was using a grain sack in which one side was not wide enough to cover the top, I made cuts on the bottom side, so I could create a piece large enough for the top of the cushion. If you are here, you are likely to know that vintage hemp linen is my thing. The quality and history of the fabric is very special to work with. Here is a list of some of my favorite shops to buy this kind of fabric: Brocante und Antikes, Objekts1, Grain Sack, Linens by Sabine, Antique Monkeys, The Textile Trunk

DO NOT FORGET TO ADD 1/2 INCH ON ALL SIDES FOR SEAM ALLOWANCE

2. Next up is cutting out the sides of the cushion. My cushion was 3 inches tall so I cut one strip that was 4 inches that was long enough to wrap around both sides and front.

3. Then I cut two 4 inch wide strips long enough to cover the back. These are used for the zipper that will go in the back of the cushion.

FINISHING EDGES OF FABRIC

With all the pieces I used my serger to finish off all the edges. If you don’t have a serger you can do a zigzag stitch around all the sides with a sewing machine. This is important if this is a cushion that will be washed in the future. If the edges are not finished there will be a lot of fraying. I did wait to serge one long edge of the strips of fabric used for the zipper because I will likely need to cut it down after the zipper is sewn in.

SEWING IN THE ZIPPER

- Using the two strips of fabric I cut for the back zipper, I begin by making an inch fold across the long side of the strips and ironing it into place.

You can see on one side of the piece of the fabric the serged edge.

You can see on one side of the piece of the fabric the serged edge.

2. Then I sew a small piece of fabric in place on both ends of the zipper to stop the pull from sliding off, unless there is a metal stopper on the zipper already.

3. Then I pinned the zipper in place on one strip of fabric, allowing at least an inch of overlap before and after zipper handle lengthwise and enough fabric to cover one half of the zipper keeping it hidden. Using a zipper foot on my sewing machine I sew it in place.

4. Repeat with the second strip of fabric.

6. Before and after the zipper I place a couple stitches to sew the fabric together:

7. I cut my strips too wide on purpose, just to leave room for error. So now with the zipper in place I cut this finished product down to 4 inches so it is the same size as the front strip.

8. After trimming to the correct size, I serged the raw edges.

SEWING CUSHION PIECES TOGETHER

- I begin by sewing one end of the zipper piece with one end of the plain strip for the front and sides. With right sides of the fabric together. I use a 1/2 seam allowance.

- Then using this strip that has one open end, I pin the zipper in place to the top of the cushion piece exactly where I want it. Again with the right sides of the fabric together. Then I continue to pin the plain side piece until it meets the other end of the zipper. Next I connect the other ends of the zipper and plain strip and sew them together. I like to do this at this time because I always seem to get measurements wrong.

- With one side of the zipper/side piece pinned in place with the top of the cushion I sew them together with a 1/2 inch seam allowance.

- Then I pin the bottom of the cushion to the opposite side of the side/zipper piece. With right sides of the fabric facing each other. You must be very careful to line up the corners of the top and bottom at this time. I also make sure a couple inches the zipper is open so that after sewing I can completely unzip it to turn it right side out.

- Sew the bottom in place with 1/2 seam allowance. And turn the cushion right side out.

- Then you should have a finished cushion cover. Try it on. Sometimes I find corners can be tricky so I add a bit of batting in them to add a some fluff. I also will cut a couple small slits in the corner pieces of the fabric just short of the seam to avoid some pulling at the corners.

- If the cushion fits then I take the time to add another stitch all around the sides. For upholstery pieces I like to have double seams. If it doesn’t look quite right, that is what a seam ripper is for, I often have to correct sections of my cushion. I typically don’t completely start from the beginning, but I with remove a section of stitching that I am not pleased with and try again with that part. Be patient with the process, these are tricky and take some time, but its definitely worth it in my opinion.

GOOD LUCK!!!

Please email me with any questions, pennyandivydecor@gmail.com

The Makeover of Two Settees Part Two: Reconstructing the Down Seat Cushion

So as luck would have it, a couple months after I purchased the first settee for our home I was checking IG and I saw a picture of my settee for sale at Goodland Antiques. What? TWO of them exist??? I knew I wanted the second to reupholster for resale. I sent a note to Ann, the shop owner and placed my claim on it.

The biggest surprise with these pieces was the state of the cushions. The interior fabric was almost completely disintegrated. So I need to remove the feathers and reconstruct the interior cushions. I suppose if the exterior fabric did not have piping or a zipper you could just leave the exterior fabric on and make a new cover for it. But my cushions had both. In my experience, every single vintage furniture piece has a surprise or two that you find once you get to work changing things up. There really is no way that the Antique shop I purchased them from would have known that if I wanted to redo them, I would have to reconstruct the cushions. They were in perfect working order if I kept the fabric that they had on them on them. That is all you can expect when buying a piece of vintage furniture.

see the feathers are about to take flight

For the purpose of this being a tutorial, for this section I am going to go through the process that I used on the second settee to reconstruct the seat cushion. Because I did in fact learn more the second time around. Although I am pleased with the results of the first settee, the second is better.

Step 1:

I made a pattern of the seat with some paper. I did this by placing a large piece of paper. You can do this with wrapping paper. Then I carefully traced around the seat and cut it out. I double checked my work by replacing the paper on the seat and saw that there were some spots that I cut too short. I taped more paper on those edges and cut true to size.

Step 2:

Into the down feathers I went. I did my best to carefully remove the previous cushion. I tried to work on this in a clean, contained space because feathers will get everywhere and I wanted to chase down as many as could. I found the second settee’s cushion to be in slightly more intact condition, not working condition, but it at least provided more clues as how to reconstruct. The cushion was a down envelope around a piece of two inch high foam.

The cushion was a down envelope around a piece of two inch high foam. I carefully removed the foam and tried to keep the feathers contained in the original cushion cover. The foam was not in great condition, but I was able to use it as a pattern for new piece of foam. I traced the old foam piece onto a new foam piece and used an electric carving knife to cut it out.

Step 3:

I set the foam piece to the side, while I worked on redoing the envelope part for the cushion. I found that the original cushion had two thin, top and bottom feather cushions that were held together by strip of 4 inch fabric edges. The back of the cushion allowed space for foam to slide in in-between the two feather cushions. So in order to recreate this I needed 4 pieces of liner fabric (I actually just used an old clean sheet) cut to size, I cut the fabric one each 2 inches larger around the entire pattern. If I were sewing a cushion cover I would cut the pieces 1/2 inch greater than the pattern to allow for 1/2 seam allowance, and then I end up with a snug fit. But since this would be used for stuffing a plump cushion I wanted to add bit more fabric make it easier to stuff and allow room for the feathers. I also cut a strip of 4 inch fabric to go around the edges of the cushion. My cushion was 3 inches high, so 4 inches was right with a 1/2 inch seam allowance. I did not worry about adding extra fabric to this strip like I did for the top and bottom pieces.

Step 4:

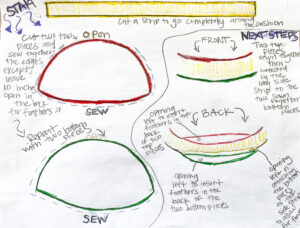

These steps are a bit tricky for me to explain, and I am visual so I attempted a diagram. Hopefully it helps, not confuses you more:

With a 1/2 inch seam allowance, I sewed two of the four of the large pieces together leaving approximately a 10 inch opening in the back to allow for stuffing feathers. Then I repeated this with two the last two pieces. I turned these right side out, which I don’t really think is entirely necessry. This will be completely covered and if you left it wrong side out it would be fine. Then I took the strip of 4 inch fabric and sewed it all the way around the edges of one of the finished larger pieces with a 1/2 seam allowance, careful not to sew the opening for feathers closed. Then I did the same for the second pieces, sewing it onto the other side of the strip. But this time I did not sew it completely around, I left approximately 24 inches open in the back in addition to the opening for the feathers. This allows an opening for the foam. In doing this it left unfinished edges on the 4 inch strip.

Step 5:

I did my best to stuff the down feathers evenly between the top and bottom cushions. I stitched up the openings for the feathers to keep them contained, careful to still allow for the opening of the foam.

Step 6:

I stuffed the foam in place in the envelope of feathers. I actually found that my foam felt a little too substantial for the cushion, if made more of a flat look versus a pillow like cushion. I believe this is because the foam was just in so much better condition and possible quality versus the old one. So I played with the size by trimming the sides to get it the right feel.

Step 7:

I am going to let you decide if this was necessary. Originally I thought that the cushion could just be stuffed into another liner and be good to go, not a complete reconstruction. Since I had it on hand, I thought I would use it. I had already cut fabric to create this:

– I did this using duck canvas, leaving an extra 2 inches on all sides of the pattern and cutting a 4 inch strip for the sides.

-I sewed the 4 inch strip completely around the top.

– I connected the ends of the 4 inch fabric and sewed those together.

-Next is sewing the bottom part to the other side of the 4 inch strip. leaving about 20 inches open to allow for stuffing the cushion in.

-Turn the piece right side out. And stuff the cushion in place. Finally stitch up the back opening.

Step 8:

To add a little extra padding and making the cushion have a full look, I added a layer of Dacron. I wrapped the cushion carefully in Dacron as not to change the shape of the cushion. If you prefer more precision you could use the pattern of the seat and cut two pieces allowing an extra 1/2-1 inches on each side for stitching and 4 inch strip for the sides. When the Dacron is in place, I secured it with a loose hand whip stitch. This completed the reconstruction of the cushion, and in the end I had a very high quality cushion that used all the precious down that was still in excellent working condition after decades of use.

Nice and comfy, this one was probably the cushion for my settee, I do my best to keep my dogs away from items I try to sell. But sometimes they do sneak in there.

Next up is making the cushion cover…

The Makeover of Two Settees Part One: Removing Upholstery Tacks and Adding White Wax to the Wood

Last summer I stopped by one of my favorite local antique shops, Goodland Antiques in Bayview. As I entered from across the room, I spotted THIS beauty. I couldn’t rip the price tag off fast enough in order to stake my claim. I have done many settee makeovers in my day, but the shape of this, the tone of the wood and the perfect caning made me realize this was a special piece.

I brought it home with a happy pickers glow on my face. I was going to try really hard to find a spot for it. The thing about my home is it is on the smaller side, there really is not any space to add pieces that aren’t actually utilitarian. I have come to realize that even if pieces are extra special, if I try to squeeze them into my house just to own them, I find the clutter isn’t worth it. It doesn’t bring me joy. Settees can most definitely be useful, but they can also just be a fancy space filler if you have space.

When I got home I realized that it might be a good option to use at my dining room table. I did need two more seats at the table. It unfortunately was a bit too short. So I had the idea of adding casters.

This was a bit of hope and prayer situation, but I was ready for the challenge since I was desperate to make it work in my home. The legs are solid wood, but they are on the thinner side, and time would only tell if they were strong enough to manage casters. I ordered these casters off of amazon and carefully drilled holes in the bottom of the feet to to insert them. If you try this, take your time drilling, with solid wood I found it easy to get the angle wrong. I did get the angle wrong on one leg, but I was able to correct it by adding wood glue and small wood dowel, then starting over again after the glue dried. They seemed to hold fine. But these wheels only rolled front to back, it was not user friendly for as much as this thing was going to get rolled. Then I changed them out for this set. The set I purchased had brakes, but this manufacture seems to not be offering those right now. We actually never use the brakes, so I don’t believe it makes much difference. They totally work!!! We are in nearly 9 months of using this at our only eating table with a family of 6. I am so happy. My kids love sitting in it and eating.

We have since added layered rugs to our dining room and the casters still work great

The height is ideal for a spot at the table. In a perfect world the settee would slide right under my table. It doesn’t. But my world is surely not perfect, and it doesn’t bother me.

I had plans to give this a fabric overhaul. The first step in doing that is removing the tacks and trim on the bottom. I have a confession…I have been doing upholstery for at least 7 years and I have always removed tacks and staples with a flat head screwdriver and pliers. It works, you have to be careful not to damage wood though. Anyway, I thought I would try this little tool that I found for around $25 on amazon. HOLY MOLY!! This was so much easier!! I know that starting out DIY projects its a pain to invest in all the tools not knowing if you would ever need them for another project. But this was worth it for me, even if I just used it for this project, it likely saved me a couple hours of work. And those couple of hours of removing tacks from furniture is not the most pleasant couple of hours. That is definitely not the fun part of reupholstering a piece.

The other change I made, was that even though I loved the tone of the natural wood I wanted to soften it up a bit. This wood did not have a high gloss finish on it so I knew it would take to a layer of white wax really well. I used Miss Mustard Seed White wax to cover all the wood. I used a wax brush to make sure that all the caning got a somewhat even coverage. A trick that I have learned is that if you apply the wax, let it dry, and you happen to find areas where there are clumps you can apply some clear wax over those areas to work out the white wax to more even coverage. The change was very subtle, but it meant a lot to me.

If you look closely you can see on the left its bare and the right has the white wax applied

This is the complete white wax look

During the next part of this project (which actually turned into PROJECTS). I will go over the process of making the cushion. It got really messing, but 1000 % worth it.